Huaxian Optics - Capacitor Busbar Detection Solution

Time:2023-11-14 10:12

view:

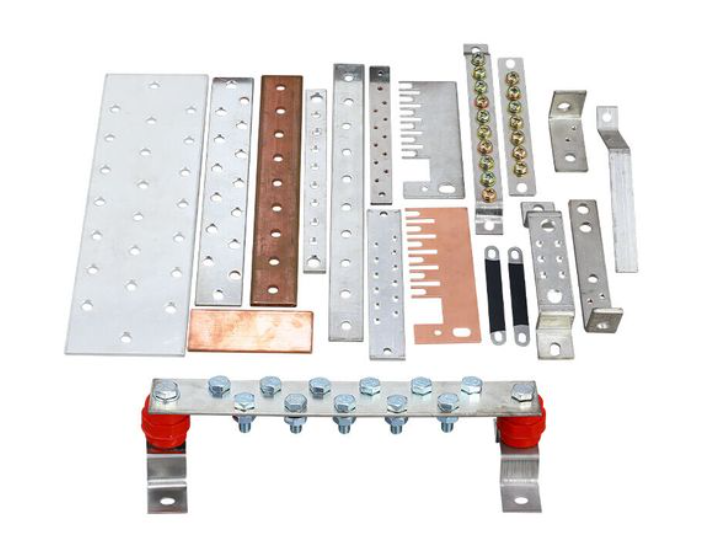

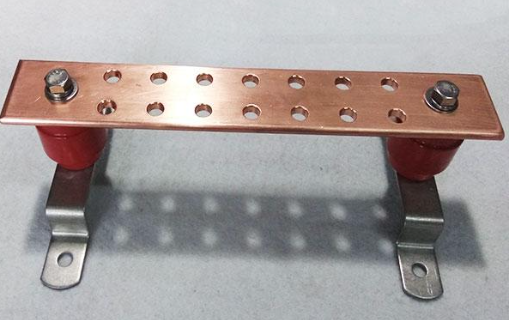

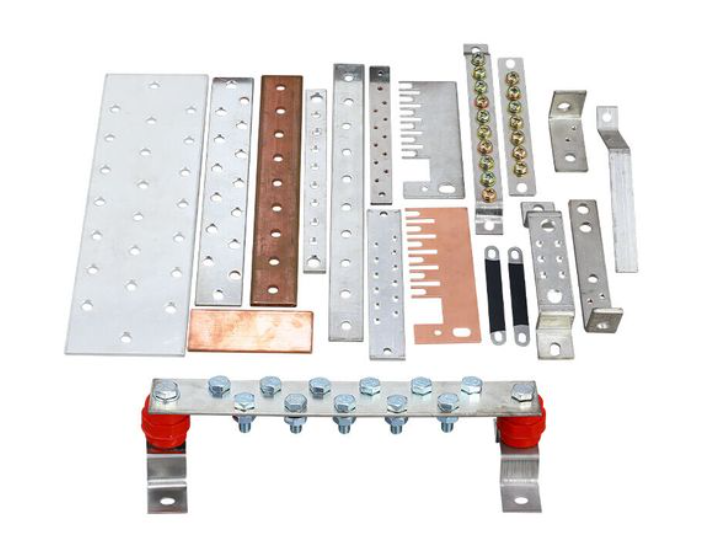

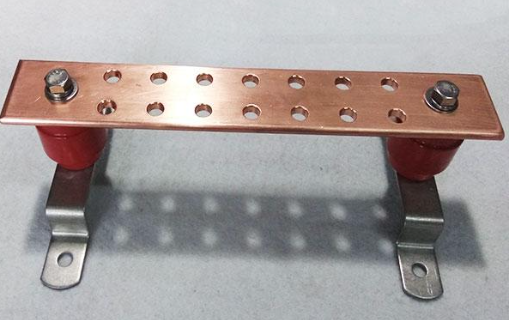

Nowadays, new energy vehicles can be seen everywhere in the streets and alleys. Among the automotive electrical components that attract a lot of attention, in addition to conventional high-voltage components such as high-voltage connectors, high-voltage wiring harnesses, fuses, and relays, there is also a type of non-standard components that also play an important role in the transmission of high voltage and large current. It is the busbar, the connecting conductive component of new energy vehicles, especially in the power (electric drive) system of new energy vehicles, which must carry large currents.

Since humans invented electricity, busbars have been inseparable from ultra-high voltage and large current transmission. They have been widely used in fields such as electric power, communications, new energy vehicles, energy storage, and military industry. Busbars can generally be divided into copper busbars and aluminum busbars according to their materials. The electron microscope plays a very important role in the quality inspection process. Electron microscopes are able to provide higher resolution and greater depth than traditional light microscopes. In busbar inspection, electron microscopes can help researchers observe and study its microstructure and composition.

Busbar:

EOC-300 ultra-depth of field 3D digital microscope, 40x-480x real-time magnification, 3um accuracy, can measure roughness, height, depth, flatness; X/Y-axis moving platform and +90° tilted z-axis platform, easy Achieve multi-directional detection, you can observe locations that cannot be observed with traditional microscopes without tilting the sample; real-time photo taking function, store backup/share data; high-definition lens, standard optical magnification: 0.6x-7x adjustable, equipped with Z-axis high-precision motor , the drive focusing is more accurate; it is easy to operate, automatically reads the contour difference, realizes high-precision automatic measurement, and greatly improves the detection efficiency. The measurement software uses 3D modeling and super depth-of-field image synthesis, which is suitable for depth measurement of step surfaces, blind hole grooves and irregular-shaped products; applicable fields: hardware and plastics, microelectronics, powder granular materials, metal parts, new energy vehicles, Jewelry.

The EOC-300 ultra-depth-of-field microscope can inspect the appearance of the busbar, including whether the size, shape, surface smoothness, surface oxidation degree, joints, etc. of the busbar meet the requirements. After ultra-depth-of-field synthesis, three-dimensional detection of busbar burrs is realized to make failure judgments. The following is the rendering of EOC-300 microscope inspection.

Electron microscopes are widely used in the automotive electronics industry. It can help researchers better understand the microstructure and composition of the busbar and further improve the performance and quality of the busbar. The application of electron microscopes will make greater contributions to the development of the automotive electronics industry.