The structural mode of the LCD screen is two-piece superposition. The ultra-thin nature of the double-piece glass determines its brittleness. It is prone to chipping when cutting, and chipping affects the strength of the glass. Therefore, the amount of chipping caused by the cutting method is very important.

(Laser cutting has obvious advantages in LCD special-shaped cutting)

Ultra-fast laser cutting of full-screen displays utilizes the self-focusing phenomenon of the laser within the material for cutting. When an ultra-high peak power laser is focused inside a transparent material, the nonlinear polarization caused by light propagation inside the material changes the propagation characteristics of the light and focuses the laser on the wavefront. This phenomenon is called self-focusing. The super-intense beam formed by self-focusing forms a thread with a diameter of about 1 μm inside the glass. The high peak energy directly vaporizes the glass where the thread penetrates, forming a hole, which can be cracked easily and efficiently by applying external force.

As laser cutting is used more and more widely in the LCD industry, module manufacturers have also increased their control over the size of cutting marks. The distance between laser points is as small as more than 1 micron, requiring a higher-definition microscope for magnified observation. And carry out dimensional measurements to achieve the stability of laser cutting.

As shown in the picture above, the measurement distance of L1 is 0.6324 microns, and the measurement distance of L2 is 1.5642 microns; this picture was taken using EOC Huaxian Optics P series high-definition microscope, infinity APO objective lens system, equipped with 4K high-resolution imaging system, optical magnification 100 times, electronic magnification Capture and measure in real time at a magnification of 3000 times.

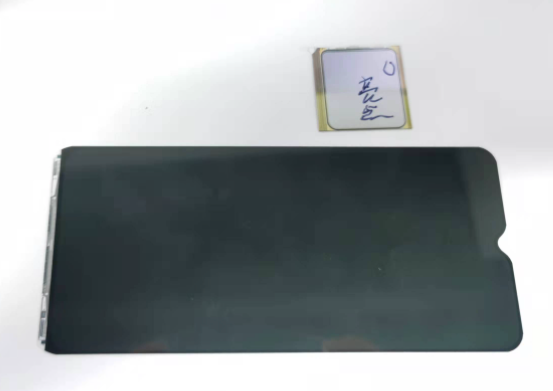

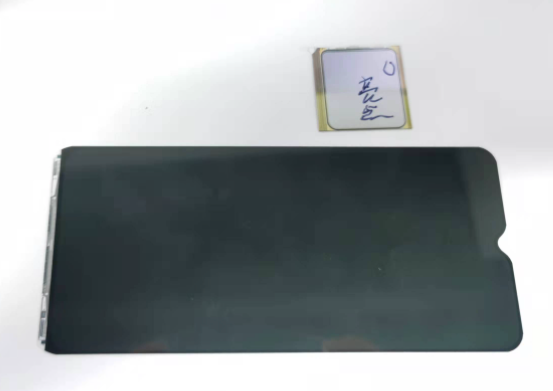

The attached picture is taken with an optical 50x objective lens and an electronic magnification of 1500x.

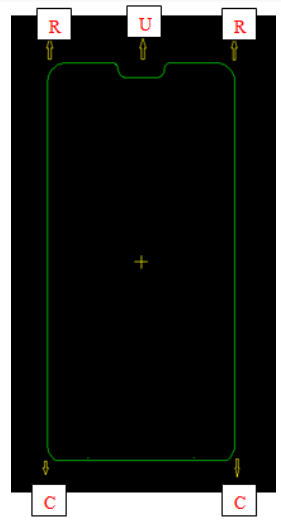

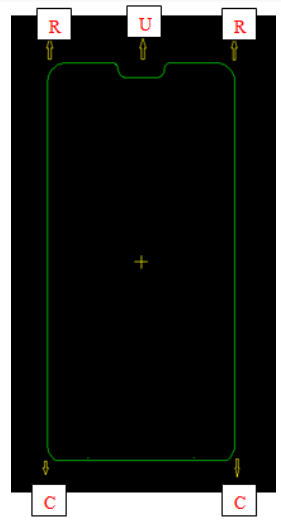

Microscope configuration diagram. Equipped with a 27-inch high-definition 4K screen, equipped with image storage and measurement. The software is equipped with 2 magnification windows, which is helpful for edge extraction and measurement of laser black spots.