Porosity refers to the ratio of the voids inside the material to the total volume in the apparent volume of the granular material. Porosity includes true porosity, closed porosity and pre-porosity. Porosity is related to the shape, structure and arrangement of solid particles in porous media, and is an important parameter affecting the fluid transmission performance in porous media. The porosity or density of a material directly reflects the density of the material. A material with high porosity means less dense. As we all know, the composition of alloys, heat treatment processes, and hot and cold processing processes directly affect the changes in the internal organization and structure of metal materials, thereby changing the mechanical properties of the parts. Therefore, using a metallographic microscope to observe, inspect and analyze the internal structure of metal is an important means in industrial production.

BA310met

BA310met

Metallographic microscopes can visually detect the microstructure of metal materials, such as raw material defects, segregation, primary carbides, decarburization layers, nitrided layers, and organizational composition in different states such as welding, cold working, casting, forging, heat treatment, etc., to determine the material. Pros and cons. The Huaxian Optical BA310met metallographic microscope used in this inspection can detect grain size, inclusion inspection, heat treatment status, and porosity. It uses an infinity flat-field chromatic aberration correction system, which effectively eliminates stray light and greatly improves imaging contrast (contrast) and clarity. It also provides dark field, polarization, differential interference (DIC) and other observation functions to easily cope with observation needs such as quality management and manufacturing process inspection.

Detection Systems

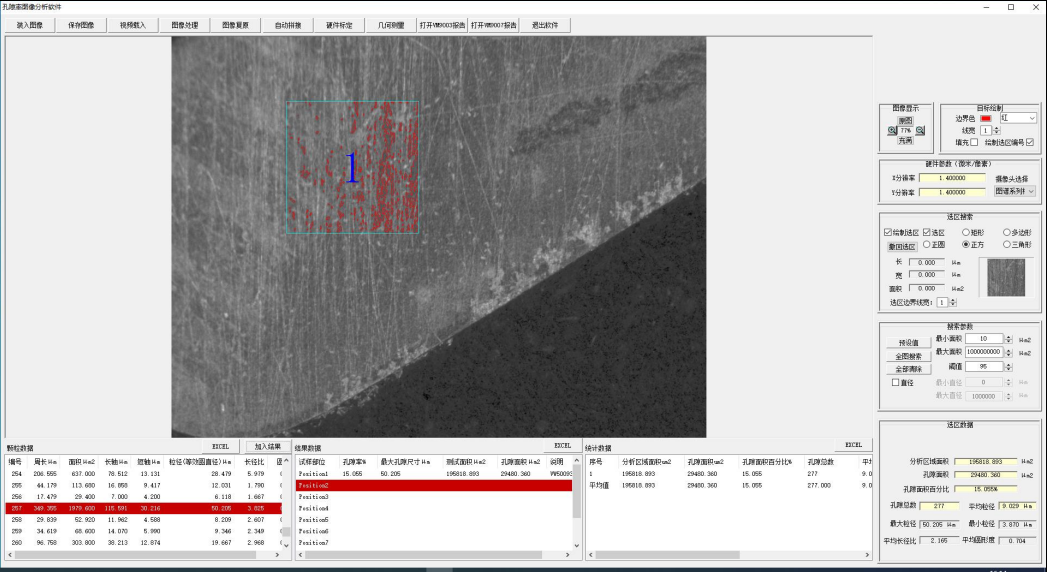

It is a professional porosity analysis system in the industry, with simple operation and accurate and reliable measurement results. The inspection classification data can be customized according to the special requirements of users, and is well compatible with Guangzhou and domestic standards, custom standards, etc. Supports the definition of technical specifications and outputs evaluation results.

Features of porosity analysis system:

★Automatic stitching of images.

★Automatically calculate the major axis, minor axis, area, aspect ratio and other morphological parameters of each particle.

★Supports VW50093 and VW50097 standards, automatically calculates the level.

★Automatically generate graphic reports, which can be saved in WORD, EXCEL, PDF and other formats.

Report

The test sample this time is metal material aluminum steel, with inspection reports at 20x and 50x, the details are as follows:

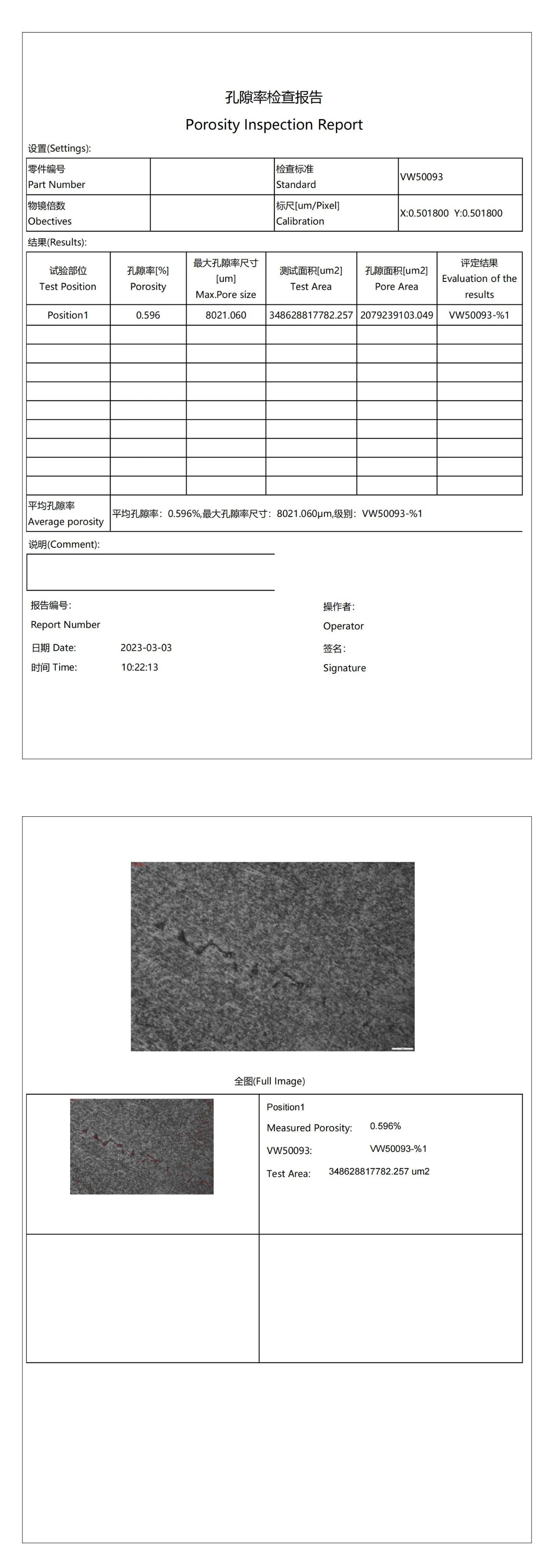

Porosity 20x inspection report:

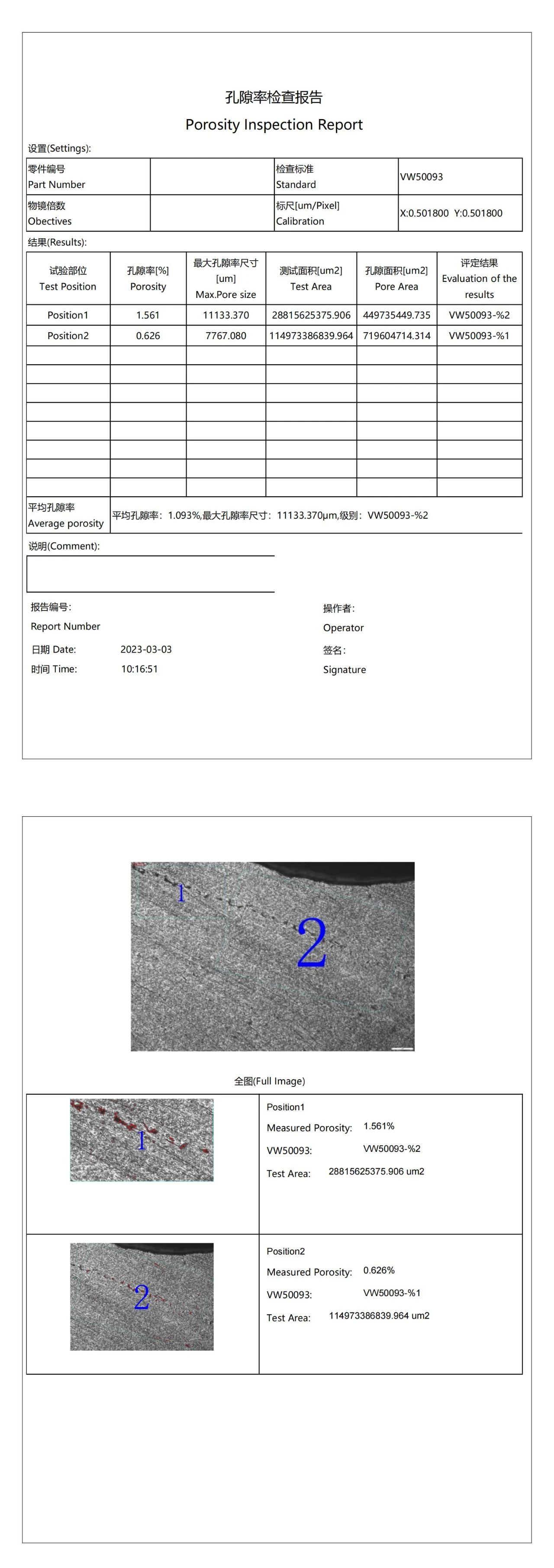

Porosity 50x inspection report: